Xaba raises $6M from Hitachi Ventures to build synthetic brains for industrial robots

XABA, a startup to build artificial brains for industrial robots that contain a zero symbol, has announced that it has obtained a $ 6 million seed investment led by Hitachi Ventures.

Toronto Startup said the extension of its seed round will accelerate the deployment of the Acting Robots and Cognitive Control Systems.

Hitachi Ventures led the tour using funds from its new fund of $ 400 million, with the participation of Hazelvief Ventures, BDC, Exposition Ventures and Impact Venture Capital.

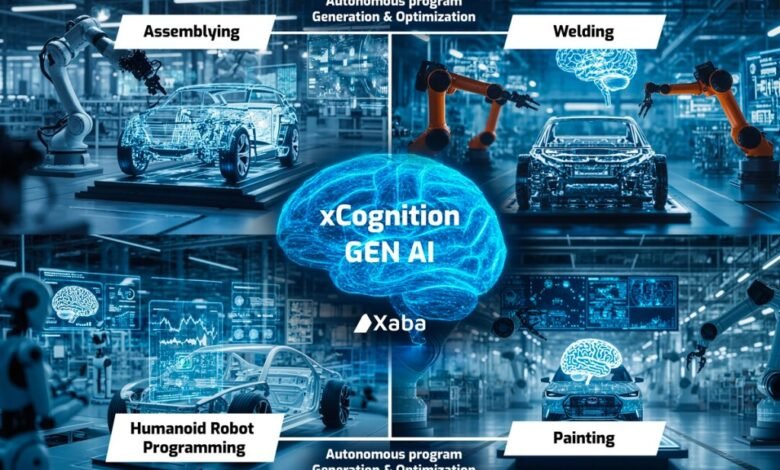

XABA is a pioneer in artificial artificial intelligence application (AI) to reshape manufacturing processes. Its pioneering product enables xcoition, industrial robots and cooperative robots (Cobots) with awareness and awareness AI, allowing them to independently generate programs and implement complex tasks such as welding, drilling, assembly and additional manufacturing.

By integrating intelligence in the actual time in automation, XABA solutions significantly reduce publishing costs and enhance the quality of manufacturing, consistency and flexibility. The company said it targeted the chance of 9 trillion dollars. The deficiency of skilled robots and control engineers creates more challenges for companies to effectively expand automation.

Massimiliano Morozi, CEO of XABA, said in an interview with Gamesbeat that industrial automation is still very ineffective, relying on old control units, solid programming and wide manual intervention. The programming and publishing of industrial robots alone cost the industry $ 7 billion annually, with 80 % of automation costs caused by manually developing logic of industrial control units.

“Our vision is to disrupt the giants. What we develop is what I call the artificial brain of information or cognitive control.”

Similar to what Open AI does for AI’s natural language orders, Moruzzi said that XABA is reshaping the factory language so that it can enable automation better, with the fact that the result is not better for industrial purposes, but also human supervision and human support.

Obstetical AI Industrial devices from XABA with cognitive intelligence, allowing them to adapt to tasks, improve and implement them accurately. In essence, there is XCOOTITION, which works as a kind of “AI Open for Industrial Automation”-fully automated industrial robots and machine programming for any task with automatically generating both partial programs and all the logic control system logic (PLC) required to bring any machine. In essence, this automation paid self -programming robots can easily move from “text to work”.

“Traditional robots systems require intense programming, continuous human supervision, conflict with the fluctuations of the real world, in engineering, practical parameters, materials, and the main performance indicators of production,” said Morozi. “We redefine automation by enabling robots and machines to improve and implement complex tasks with minimal programming. The result is a significant decrease in waste and reaches 10x in costs.”

XABA: The Self -Self -Control Self -Automation Automation System

With XABA, manufacturers can simply describe automated operating objectives, main performance indicators, production, operational tasks in text or human readable job specifications. From there, Xcolition and PLCFY create the desired code independently, allowing robots and production lines to work independently with the ability to adapt in actual time.

Digital twins aim to master factory designs before being built in the material world. But Morozi said that this concept must be renamed “automatic reality”. He said that industrial managers need a machine that can synthesize the human experience and transfer it to a robot.

“In XABA, we develop the basic artificial intelligence of automation, which means, for example, that my artificial mentality captures the electromechanical physical model of the machine. Why do I do this? Because the experiment is not inside to the encyclopedia that opens AI in order to convert this text until the technique of the so -called data.

What is ontology?

He said that ontology is its part in neuroscience data.

“It has the ability to do what a person can do only at the present time, which is called kidnapping. The kidnapping means that the brain is able to formulate scenarios. “I am taking advantage of the old data from the factory now. What I have done during the past few years is to seize knowledge from the Legacy that comes from the operator.

The result is to publish faster, reduce stopping time, and more intelligent and more flexible automation through industries through:

- Automated learning model in physics: It works as a real digital twin, it accurately repeats environments in the real world, and adapts to different machines and movement platforms for accurate improvement in actual time.

- Robots and PLC AI Code Generation: Royal IQ models independently create both robotic programs and PLC code by understanding the workflow and machine logic. This reduces publishing time by up to 80 % and removes manual coding.

- Real time learning unit: This data unit operates on GNNS networks, and understands complex relationships between machines, sensors and operations. It ensures dynamic adaptation and continuous improvement.

- Cognitive control framework: AI’s global platform that is smoothly integrated with any automatic system, CNC or PLC control unit, supports both old and modern equipment.

“Industry 4.0 promised smart and independent factories-but it was often stuck in the experimental disinfectant, which is hindered by solid, secondary and old infrastructure systems,” Jiathri Radkrichnan, a partner in Hitachi Vetshers, said in a statement. “XABA breaks this serum. By giving industrial machines the ability to self -learning and self -programming through gym, XABA turns the vision of smart manufacturing into a fact -developmental fact today.”

AI’s AI in XABA is already converting space, cars and high -resolution manufacturing by eliminating costly reformulation and manual modifications in areas such as car manufacturing.

AI works on XABA to improve and falsify aluminum pouring, allowing robots from minerals accurately with tolerance to machines – reducing assembly costs, reformulation, and production time.

It also pits a robotic on a large scale. Morozi said that manufacturers have achieved production rates faster 10 times with a significant decrease in capital expenditures. Unlike traditional systems that require solid programming and manual adjustments, Xaba’s AI allows robots to reinstine different parts and operations smoothly without costly stopping.

XABA also performs automatic welding. XABA’s AI automatically automate MIG (Esitable Metal Gas) and TIG (Tungsten GAS) and laser welding, ensuring fixed and high -quality production via production lines while speeding up production tables.

XABA deals with 3D printing on a large scale. The XABA XABA system improves molten sedimentation modeling (FDM), preventing Delaging, collapse, and distortion. It allows the manufacturers to set print parameters in the actual time, which improves reliability and reduces material waste.

“Max and his team created a bold new scheme for the future of robotics and industrial automation,” said Marco Andriano, CEO of Fives Cineetic Corp. “With the perception of XABA with XABA, we offer smart systems that convert contracts from inefficiency into developmentable manufacturing environments – a solution to the most programming and production challenges facing the industry today.”

The company has 24 people working for it. The team includes artificial intelligence scientists, mathematicians and mechanic experts. They run AI AI automation laboratory.

Moruzzi believes that LLMS models are not the correct technology of automation because the founding model behind LLM depends mainly on a set of weight factors. It is like using the encyclopedia to answer a question about whether the robot should rotate left or right. Moreover, LLMS is vulnerable to hallucinations, which is bad in industrial environments.

This means that the range that may collect or not gather the indications in the way that gives you the correct response, he said. Moruzzi designed artificial intelligence to be completely different, as it builds a system that can create artificial data on its own.

He said: “Your mind is not llm.”

Morozi said his company entered production in the coming months. He pointed out that there are only about 4.4 million industrial robots in this field now. This is almost nothing, taking into account the number of people. The reason is that their brains – a little more than industrial control units – are not good enough. They are like “empty boxes”.

“For this reason, I build a perceived brain,” he said. “This is the way to speak with the material world.”

Don’t miss more hot News like this! Click here to discover the latest in Technology news!

2025-04-14 16:00:00