AI Drives Battery Innovation at Microsoft, IBM

When Microsoft researchers in 2023 identified a new type of material that can significantly reduce the amount of lithium in rechargeable batteries, I felt that she was combed through a straw pile in record time. This is because their discovery started as 32 million capabilities, and with the help of artificial intelligence, it produced a promising candidate within 80 hours.

Now researchers in the national laboratory plan in the National Pacific Ocean to synthesize and test new materials, NAxfor me3 – xYcl6In preparing the battery. It is one of the many battery chemistry created from artificial intelligence that makes its way to the real world.

The Microsoft experience began when the researchers wanted to explain how artificial intelligence tackled the needle problem in Histak of finding useful new materials and materials. They decided to search for new candidates to obtain a rechargeable battery electricity, because the best electrolyte can make the batteries safer while improving performance simultaneously, Nathan BakerMicrosoft Project Commander Azure quantum elementsA program to accelerate chemistry and material research through advanced computing platforms from Microsoft and AI.

“Our goal was to take one of these artificial intelligence models and show the promise to accelerate the scientific discovery – as it is suitable for 32.5 million candidates for materials and show that we can do this within hours, not years,” says Baker. Their model, the M3Gnet framework, is called the accelerated simulation of molecular dynamics to assess material properties such as atomic spread.

First, Microsoft researchers asked the model to drop new chemical elements in well -known crystalline structures and determine the resulting molecules that will be stable, a step that reduced 32 million candidates that started to half a million. AI then examined these substances based on the chemical capabilities needed to make the battery action, which cut the swimming pool to only 800. From there, traditional computing and old human experience has determined the new materials that can operate inside the battery and use 70 percent of lithium less than rechargeable batteries in commercial use today.

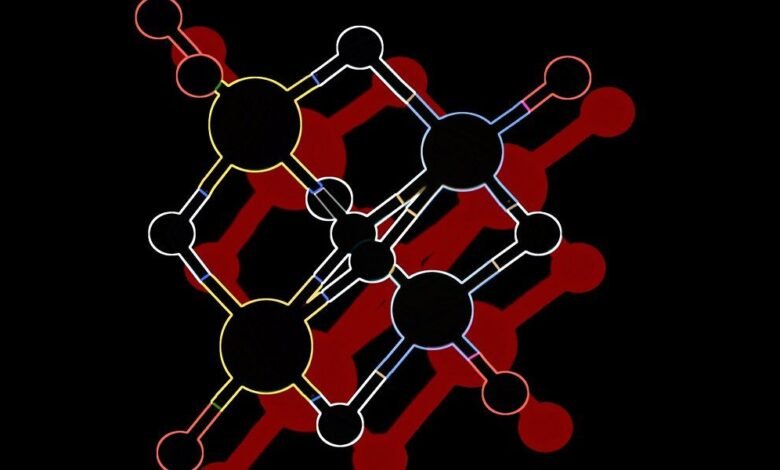

The role of artificial intelligence in the battery design of the next generation

The Microsoft team is not alone. Throughout the world, researchers are busy with an attempt to develop designs of the next generation to replace or improve lithium ion batteries, which use large amounts of rare, expensive and difficult elements. New battery designs can use more abundant materials, reduce the risk of fire from lithium -based liquid electrolytes, and fill more energy in a smaller area. Chemistry is awaiting this to discover it, increasingly, researchers harness artificial intelligence and machine learning to do sorting through the data mountain.

Dibakar Data, Associate Professor at the New Jersey Institute of Technology, who published a study in August / August to determine five filled materials for batteries that would surpass Lee Ion. Datta team works on a multi -equivalent battery: Use multi -equivalent ions that can carry multiple charging levels instead of the individual charge carried by a lithium battery.

This would give the battery a larger energy storage, but it also means working with larger ions than higher elements on the periodic table, such as magnesium and calcium. These larger ions will not necessarily fit with current battery designs without breaking or breaking the elements, says Data. His new study used what he calls an automatic cryptocurrency for crystal spread (CDVAE), which can suggest new materials, and a large language model (LLM) can find materials that will be the most stable in the real world. Of a group of millions of possibilities, the approach found five porous materials of the right size that could perform the task.

Directing the artificial intelligence model to chase it through an endless space of possible materials is the turning point in this field. The key to its use as a research partner is to find a happy way between a model that works quickly and a model that provides completely accurate results.

“You have to pass all the widening and depth,” says Seldk. The depth, because the design of these things requires a lot of deep scientific knowledge about characteristics, engineering, chemistry, and breadth, because you must apply that knowledge through an endless chemical space. “This is where the promise of artificial intelligence comes.”

Search for artificial intelligence battery technology in IBM

The researchers in IBM followed an approach that AI moved to determine new electrolyte candidates, which included identifying chemicals with electric conductivity much higher than the lithium salts used in the current batteries. The typical electrolyte can contain six to eight components, including salts, solvents and additions, and it is almost impossible to consider all groups without Amnesty International.

To reduce the stadium, the IBM team has developed a chemical institution trained on billions of molecules. “They are taking the basic language of chemistry,” says Young-Hye Na, the main employee of IBM Research. Its team then train these models with battery -related data so that artificial intelligence can predict important features of battery applications on standards of individual molecules to a full device. NA described the work on a paper published in August in NPJ’s arithmetic materials.

Since the work is looking for new groups of current materials instead of using artificial intelligence to create new strange materials, its potential to help build a battery tomorrow is more promising, says NA. The IBM team is now cooperating with an unannounced EV manufacturer for high -performance electrolyte design.

IBM is not limited to the artificial intelligence of batteries to search for promising materials. Usually, when artificial intelligence reveals a promising new material, the next step is for experimental to collect things, try them in the laboratory, and one day to test them in a real device. Automated learning (ML) will help researchers in this test step as well.

IBM tests the ability of the new battery settings in the new world by building their digital-virgin models that allow researchers to predict how to deteriorate specific battery chemistry over the life of a number of countless energy sessions. Tudoro Lino, the distinguished employee of IBM Research, says that the model, which was developed in cooperation with the battery operating company, can predict the long -term battery behavior in less than 50 energy -based energy courses.

The next stage of artificial intelligence battery research is quantum. While Microsoft and IBM pushed towards the capabilities of quantum computers, both of whom see their promise to mix complex chemistry without shortcuts or concessions. NA says that although the current artificial intelligence is a crucial tool for investigating battery chemistry, the next step – teaching full EV battery packages, for example, taking into account all the variables they face in the real world – will require quantum computing power.

Baker says: “We know that classic computers have problems generating accurate answers to complex materials, complex molecules, and complex materials. So our goal now is to change the way the data is created by bringing the quantity to the loop so that we have higher accuracy data to train ML models.”

From your site articles

Related articles about the web

Don’t miss more hot News like this! Click here to discover the latest in AI news!

2025-10-01 14:00:00