Lilac Solutions is planning a lithium empire from the shores of the Great Salt Lake

The Great Lake Solt is not a clear place to develop a Li -mine. The Salon Sea includes lithium concentrations less than 200 parts per million. Argentina, where Lilac has another test facility, with resources of more than 700 parts per million.

Here on the Great Lake Salt? “It is 70 parts per million,” Reef Soleil, CEO Lilac, born in Australia. “So if you have a soccer field with 45,000 seats, this will be three people.”

For Lilac, this is actually a feature of site. “It is a very good demonstration of the ability of our technology,” says Solly. He explains that Lilac devices can extract lithium at high purity levels of saline solution with low concentration, he says, proves multiple types. This was not the reason for choosing the site, though. “The state of Utah is a friendly mining country,” says Elizabeth Bond, Vice president of Communications. Although the lake water has low concentrations of lithium, the extraction of a saline solution simply calls for a hose in the water, while other sites require dug a well at a large cost.

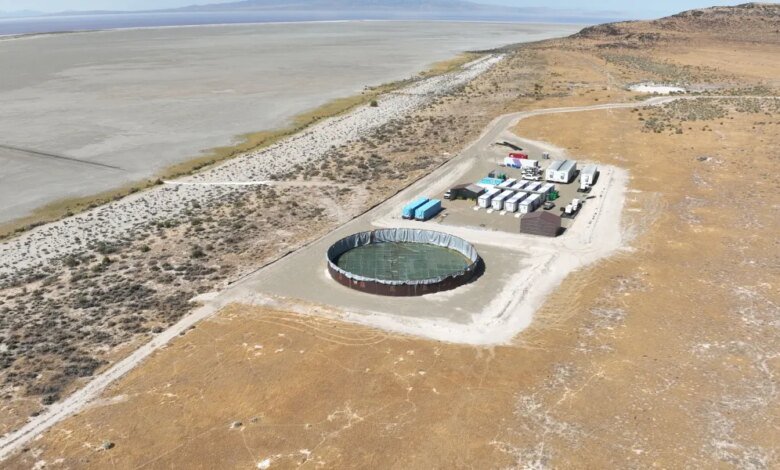

When I accompanied Soleil to the test site during my tour, our way after the unpaved boycott routes lined with fields of wild sunflowers. The attachment itself is a little more than a variety of converted charging containers and two mobile trailers, one to be the main office and the other as a field laboratory for sampling test. It is outside the network, relying on diesel generators that the company says will be replaced with propane units once this site is converted into a permanent facility, but it can be eventually replaced by the Earth’s Energy Technology in a hot rock resource located nearby. (Solar panels cannot be able, the power supply can not be provided by the facility.) But it depends on its connection to the great salt through this lengthy hose.

Alexander Kaufman

Passing the lake water, which was pumped, through a series of filters to remove solid materials until they end in a ship full of ceramic beads designed specifically for the company, made of patented material that attracts lithium ions from the water. Once saturated, beads are placed by washing the acid to remove lithium. Then the remaining saline solution is tested over and over again, and as soon as it is considered safe to release it again to the lake, it was pumped to the beach through a tube issued in Khartoum. Meanwhile, the lithium solution is stored in the tanks on the site before shipping to the processing factory to be converted into a battery -category carbonate, which is a white powder.

“As a long -term technology provider, if we have contracts for lithium demand, they want to put their technology as something that can benefit from a group of markets,” says McBridide. “Getting a technology can be economically recovered from resources in various types of environments is an attractive proposal.”

This test land will not remain for a long time. During my visit, the Lilac crew began to pack the site after completing the illustration test. The results that the company shared exclusively indicate with the success of destruction, especially for low -grade saline solution with many impurities: Lilac equipment has recovered 87 % of the available lithium, on average, with a purity rate of 99.97 %.

Don’t miss more hot News like this! Click here to discover the latest in AI news!

2025-10-07 09:00:00