How 3D printing could make better cooling systems

“The thermal exchanges are among the industrial economy. It is an essential part of every machine and every system that drives energy,” says William King, Professor at the University of Illinois Urbana Chambine and one of the authors of the new study. He adds that the current designs tend to prefer straight lines, right angles and round tubes.

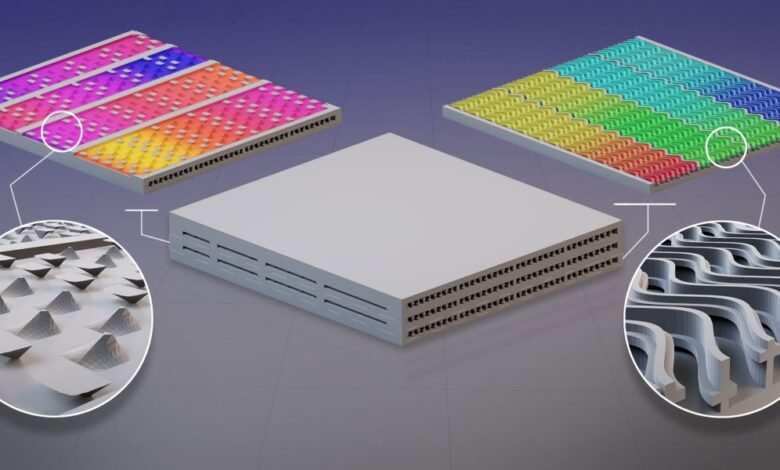

King and colleagues use 3D printing to design a heat exchanger that includes features to improve heat movement, such as wavy walls and pyramids in the form of a pyramid, which will not be possible to use traditional manufacturing techniques.

The team began to design a system based on a common cooler called R-1334A, which is usually used in devices such as air conditioners and refrigerators. When cold water reduces the coolant temperature, it changes from gas to liquid on its way through the device. This liquid cooler can then move to other parts of the cooling system, where it is used to reduce the temperature of anything from room to shelf from servers.

The best way to cool the cooler tends to involve very thin walls between the two sides of the device and increase the amount of contact made by water and cooler with those walls. (Think about the coldness you wear a thin shirt and pants and lie on the ice instead of just touching it with your glove hands.)

To design the best possible heat exchanger, the researchers used simulations and advanced machine learning models to help predict the performance of different designs under different circumstances. After 36,000 simulations, the researchers fell on the one they decided to develop.

Among the main components: small fins that come out on the side of the device that touches the water, which increases the surface area to increase heat transfer. The team also designed wavy corridors to pass the water – once again help to increase the surface area to the maximum. The simulation helped researchers know the extent of the corridors and the place of putting the fins specifically.

On the side of the devices where the coolant passes, the design includes small bumps in the form of a pyramid along the walls. This not only increases the cooling area to the maximum, but also helps in mixing the coolant while it is passed and preventing the liquid from painting the wall (which slows the heat transfer).

After settling the design, the researchers used a 3D printing technique called direct metal laser dressing, where the laser melts and coordinates together metal powder (in this case, aluminum alloy), layer after another.

2025-04-02 08:00:00